🌡️ Hot Disk Thermal Constant Analyzer – Revolutionizing Thermal Conductivity Testing! 🌟

🔍 What is it?

The Hot Disk Thermal Constant Analyzer utilizes the Transient Plane Source (TPS) method, an advanced approach that enhances the accuracy of thermal conductivity measurements. This cutting-edge instrument is widely recognized as the gold standard for testing thermal conductivity today.

✅ Key Features

- Direct Measurement: Precisely measures thermal conductivity using the transient planar heat source method.

- Wide Range: Thermal conductivity measurement range of 0.005–500 W/mK.

🧪 Sample Requirements

1️⃣ Powder or liquid samples should be at least 30 mL.

2️⃣ Powder samples may have errors due to air entrapment—compaction is recommended.

3️⃣ Sample diameter or side length: >2 cm; thickness: >200 μm.

4️⃣ Flat upper and lower surfaces are preferred, but irregular shapes are acceptable.

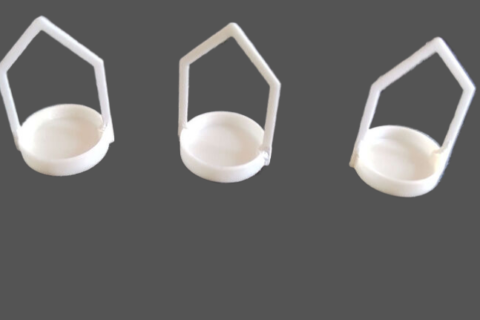

5️⃣ Two identical samples are required to clamp the probe during testing.

6️⃣ For high thermal conductivity samples (above 100 °C), recommended size is 5 × 5 cm (minimum: 3 × 3 cm).

💡 FAQs

Q: What is the relationship between thermal conductivity and thermal diffusion coefficient?

A: Thermal conductivity = Thermal diffusion coefficient × Specific heat capacity × Density.

Q: Can we test anisotropy?

A: Yes, as long as there’s a notable difference in thermal conductivity across different directions of the sample.

Q: What is the specific test method?

A: The Transient Plane Source (TPS) method (ISO22007-2).

Q: Which is better for thermal conductivity testing: the single-sided or double-sided method?

A: The double-sided method is the standard. The single-sided method is used only when sample size or quantity is limited.

🔗 Curious to know more about how the Hot Disk Thermal Constant Analyzer can enhance your testing process? Contact us today!

#ThermalAnalysis #HotDisk #MaterialTesting #ThermalConductivity #CeramXpert #Innovation #Research #MaterialScience