Oxidation Induction Time (OIT)

Oxidation Induction Time (OIT) is a key indicator of a material’s resistance to thermal degradation during molding, storage, welding, and usage.

The DSC-600S Differential Scanning Calorimeter, with its precise temperature control and heat flow monitoring capabilities, can accurately perform OIT tests on standard samples, determining whether they fall within the 30-38 minute standard range.

Experimental Procedure:

- 5-10 mg of the standard sample was placed in an open aluminum crucible, with an empty crucible as the reference.

- Nitrogen and oxygen are passed through, with a flow rate set to 50 mL/min. The furnace is purged with nitrogen for 3 minutes before heating.

- The crucible is placed in the DSC-600S, and the sample is heated at a rate of 20°C/min to 210°C, held for 3 minutes under nitrogen. Then, the atmosphere is switched to oxygen (flow rate of 100 mL/min) to measure oxidation until a significant exothermic change occurs, and the test is stopped.

- The result shows that the standard sample has an OIT of 36.69 minutes, which falls within the 30-38 minute standard range, indicating excellent heat degradation resistance and compliance with oxidation performance requirements in high-temperature environments.

This experiment strictly controlled sample quality, temperature, and gas flow conditions, ensuring the accuracy of the results and fully validating the stable performance of the standard sample in real-world applications.

Conclusion:

The DSC-600S was successfully used to conduct the oxidation induction time test on standard samples, demonstrating its effectiveness in accurately determining material properties for thermal stability and oxidation resistance.

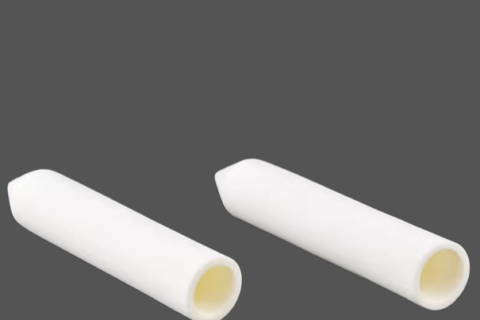

At CeramXpert, we can provide aluminum crucibles designed for high-precision tests like OIT and more. Contact us to learn more about our products.

#CeramXpert #ThermalAnalysis #DSC #OIT #MaterialTesting #OxidationInductionTime #AluminumCrucibles #MaterialsScience #HighTemperatureTesting #AdvancedMaterials #LabConsumables #InnovationInTesting #QualityAssurance