🔬 Exploring the Thermal Decomposition Characteristics of Ceramic Materials with the STA-1250 🔬

Ceramic materials are widely used in industries like electronics, aerospace, and energy due to their excellent high-temperature stability, mechanical strength, and chemical inertness. Thermal decomposition temperature and weight loss behavior are key indicators of a material’s thermal stability, which play a crucial role in optimizing processes and selecting suitable application scenarios.

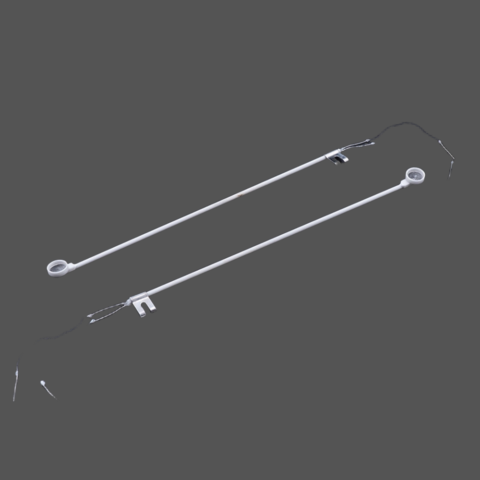

The STA-1250, featuring imported alloy sensors and an internal calibration function, ensures highly accurate and repeatable results. The furnace heating part, made with precious metal alloy wire, reduces external interference and offers enhanced high-temperature resistance.

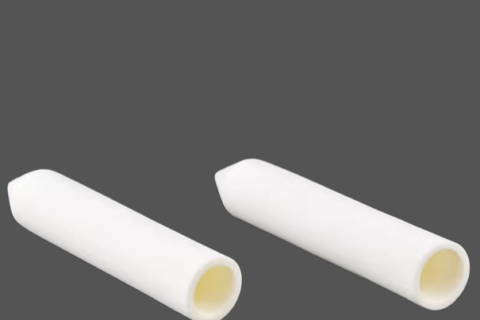

For this experiment, a precise amount of ceramic sample was placed in an alumina crucible, ensuring uniform distribution. The heating rate was set at 10°C/min, increasing from 20°C to 900°C under a nitrogen atmosphere. According to the DSC-TG curves from the STA, the ceramic sample’s decomposition temperature was found to be 217.56°C, with a weight loss of 7.93% occurring between 112.05°C and 536.02°C.

This experiment, conducted using the STA-1250 synchronous thermal analyzer, provided critical data on the thermal decomposition temperature, weight loss range, and rate, revealing the material’s thermal stability and decomposition mechanism.

As CeramXpert continues to support innovations in material science, our thermal analysis consumables will play a crucial role in breakthroughs across various industries.