Testing the Melting Point of Nickel-Chromium Alloys Using a Simultaneous Thermal Analyzer

Nickel-chromium alloys, primarily composed of nickel and chromium, are high-performance materials widely used in heating elements, aerospace, and chemical equipment due to their excellent high-temperature resistance, oxidation resistance, and electrical stability. These alloys can withstand temperatures ranging from 1100°C to 1400°C (e.g., Ni80Cr20), forming a dense Cr2O3 oxide layer at high temperatures to prevent further oxidation.

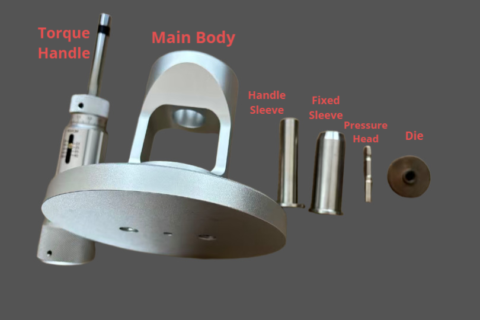

In this experiment, the STA-1550S Simultaneous Thermal Analyzer was used to test the melting point of a nickel-chromium alloy. The test conditions were set to heat from room temperature to 1500°C at a rate of 20°C/min, with a nitrogen atmosphere and a controlled gas flow of 50ml/min. A sample weight of 209.5mg was used. No significant morphological changes were observed in the alloy before and after the test.

The analysis revealed that the melting point of the nickel-chromium alloy was 1432.30°C, with no mass loss or decomposition during the process.

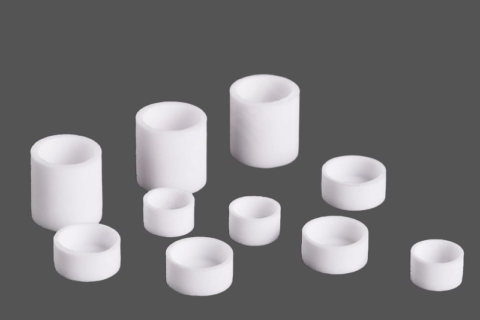

The STA-1550S provided stable performance throughout the experiment, offering reliable support for testing and accurate results. CeramXpert’s alumina crucibles, with a maximum use temperature of 1500°C, performed perfectly to meet the testing requirements.

#CeramXpert #ThermalAnalysis #NickelChromium #Alloys #HighTemperatureTesting #AluminaCrucibles #STA1550S #MaterialsTesting #MetallurgicalAnalysis #ThermogravimetricAnalysis #CeramicMaterials