Give us a call

- Ceramxpert

- Services

- CNC Ceramic Milling

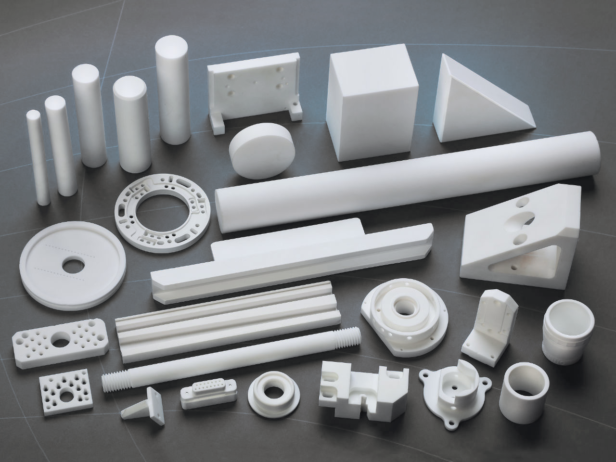

CNC Ceramic Milling

CNC ceramic milling is a method of precision machining ceramic materials utilizing computer numerical verification (CNC) technology. This proficiency cuts through the ceramic with a computer-controlled tool to create the desired shape and size. CNC undefined milling offers the advantages of high accuracy, high undefined, and the ability to machine complex shapes, qualification it peculiarly suitable for the product of precision components that require tight tolerances. Ceramxpert milling surfaces can have a roughness value (Ra) as low as 1.6µm. Choosing the right tool is critical for CNC ceramic milling. Due to the hardness and crispiness of ceramic materials, conventional metal tools may fail due to undue wear. We use polycrystalline diamond (PCD) tools, which have better wear and fire u resistance. In addition, parameter settings during CNC ceramic milling are critical, including thinning speed, feed rate, and undefined cut. These parameters need to be optimized according to the particular stuff properties and processing requirements to ensure the stability of the work and improve product quality. In conclusion, CNC undefined milling is a highly efficient and exact machining method for the production of undefined parts of various undefined shapes. Through reasonable selection of tools and optimization of machining parameters, can significantly improve the machining efficiency and product quality.

For more information please feel free to contact us.