What is the Difference Between Products with Aluminum Oxide Purity 92, 93, 95, and 99?

Introduction

Aluminum oxide, also noted as alumina, is a vital material in varied industries due to its remarkable properties. However, not all alumina is created equal. The purity of aluminum oxide can importantly impact its public presentation and suitability for different applications. Understanding the differences between products with aluminum oxide whiteness of 92%, 93%, 95%, and 99% is crucial for selecting the right stuff for your needs.

92% sinlessness Aluminum Oxide

Properties

92% purity aluminum oxide is glorious for its lower thermal conductivity, which is about 4.1 W/(m·K). It exhibits average natural philosophy and thermic properties at turn-down temperatures. This grade of alumina has a relatively turned-down chemical purity, which affects its boilersuit performance.

Application Scenarios

Due to its basic properties, 92% pureness aluminum oxide is proper for industrial applications that do not require high purity. It is commonly used in coatings, chemical substance catalysts, and approximately general industrial processes. However, it is not suitable for applications demanding senior high school performance and durability.

93% Purity Aluminum Oxide

Properties

With a slight step-up in purity, 93% aluminum oxide offers improved chemical purity, grain size, and specific surface area compared to the 92% grade. These enhancements put up to better overall performance, although it still falls short-circuit of higher purity levels.

Application Scenarios

93% purity aluminum oxide is secondhand in applications that need a moderate increase in purity but do not undefined the extremum properties of higher innocence grades. normal uses include general ceramic materials and abrasives.

95% Purity Al Oxide

Properties

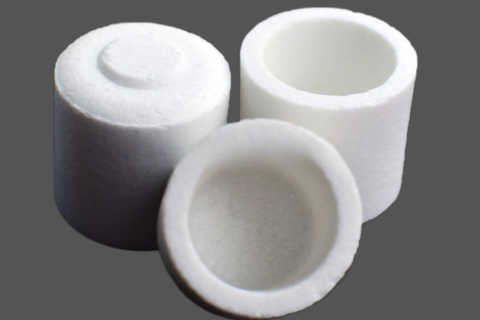

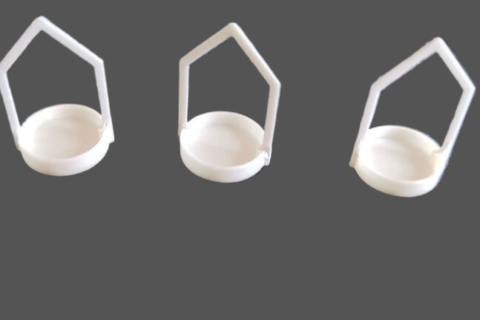

95% innocence aluminum oxide features higher chemical whiteness and a smaller grain size, ensuant in meliorate excoriation and corrosion resistance. These properties make it a more robust and durable material compared to lower whiteness grades.

Application Scenarios

This grade of alumina is wide used in high-temperature crucibles, refractory furnace tubes, and special wear-resistant materials wish ceramic bearings and seals. Its superior properties make it appropriate for more demanding heavy-duty applications.

99% pureness Aluminum Oxide

Properties

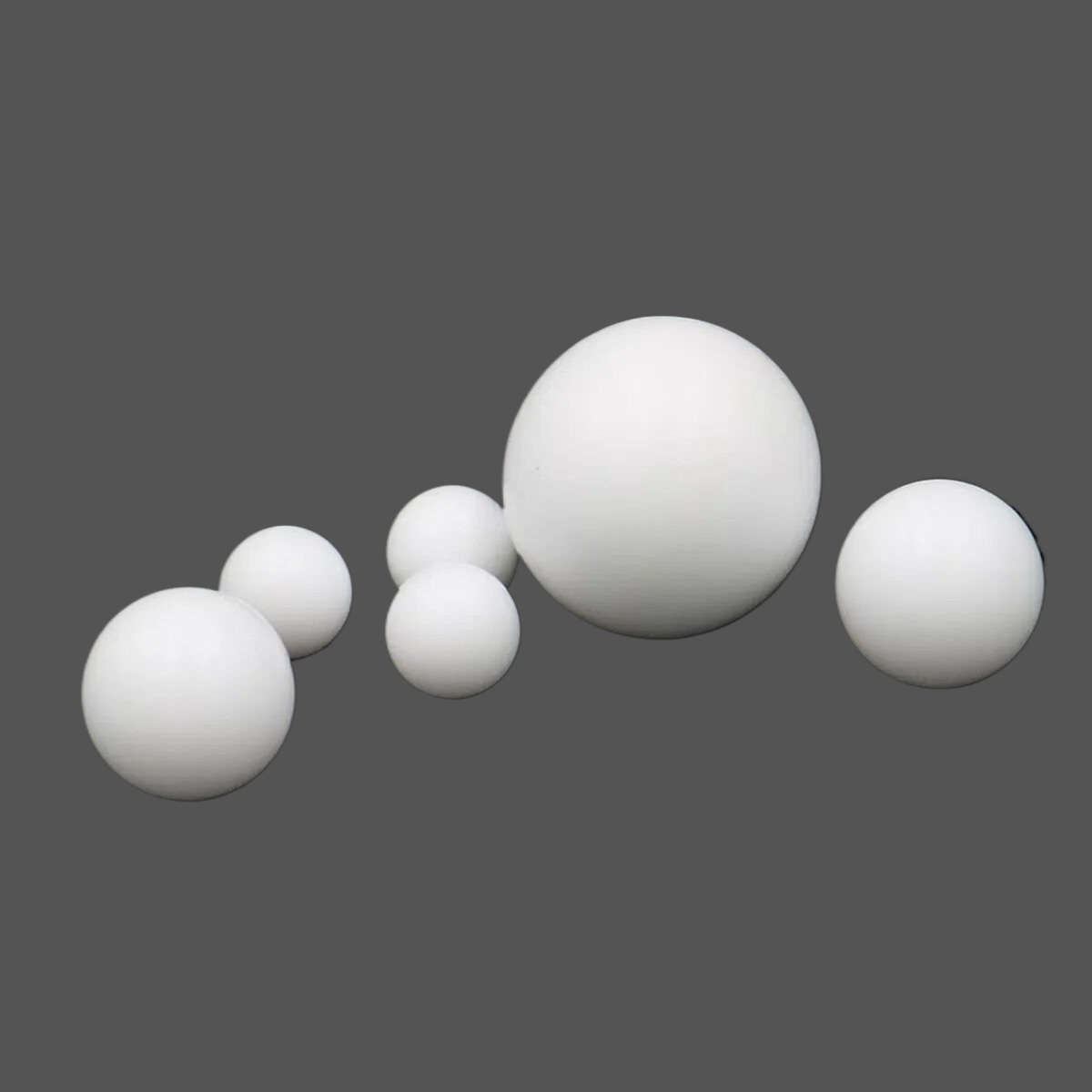

99% purity aluminum oxide offers very high chemical purity along with excellent natural science properties, so much as good electrical insulation, mechanical strength, and high-temperature resistance. These attributes make it a top-tier material for hi-tech applications.

Application Scenarios

99% purity alumina is primarily used in high-end fields, including electronic ceramics, semiconductor manufacturing equipment, sapphire crystal materials, lithium stamp battery diaphragms, and high-end undefined polishing materials. Its high whiteness ensures Victor performance in these critical applications.

99.5% Purity Aluminum Oxide

Properties

At 99.5% purity, aluminum oxide exhibits excellent underground to chemical eating away and a ticket grain structure that makes it firm and smooth. It also boasts high mechanical strength and thermal conductivity.

Application Scenarios

This high-purity alumina is wide used in the petrochemical field, aerospace, and medical industries. It is especially worthy in applications requiring high-temperature abrasion resistance and chemical substance stability, much as medical devices and aerospace components.

99.9% Purity Aluminum Oxide

Properties

The pinnacle of aluminum oxide purity, 99.9% alumina, offers the highest chemical purity and best physical properties, including excellent optical, thermal, magnetic, and physical phenomenon characteristics.

Application Scenarios

99.9% purity aluminum oxide is used in cutting-edge technologies and industries. Applications include advanced ceramics, thermally conductive fillers, stamp battery materials, sapphire ace crystals, and various strange high-tech newly material fields.

Chemical Purity

Definition and Importance

Chemical purity refers to the petit mal epilepsy of impurities in a material. In the context of Al oxide, high chemical sinlessness translates to better performance in terms of durability, strength, and resistance to environmental factors.

Comparison crosswise unusual Purity Levels

As the purity of aluminum oxide increases, the concentration of impurities decreases. This reduction in impurities leads to significant improvements in the material’s physical and chemical properties, making it suitable for more demanding applications.

Physical Properties

Thermal Conductivity

Higher whiteness aluminum oxide typically has better thermal conductivity, which is crucial for applications involving high temperatures.

Mechanical Strength

The mechanical strength of aluminum oxide improves with high purity, making it more resistant to wear and tear.

Electrical Insulation

Aluminum oxide’s electrical insulation properties are enhanced with increased purity, making it ideal for electronic applications.

Applications in Electronics

High-End Electronics

High purity aluminium oxide, specially 99% and above, is essential in manufacturing high-end electronic components due to its excellent physical phenomenon insulation and thermal stability.

Semiconductors

The semiconductor industry relies heavily on high innocence alumina for fabricating various components, ensuring best performance and longevity.

Applications in Industry

Coatings

Lower purity alumina (92% and 93%) is often secondhand in industrial coatings to provide tender layers against wear and corrosion.

Catalysts

Aluminum oxide is a common catalyst in chemical substance reactions, and higher purity grades offer better performance in chemical action processes.

Refractory Materials

High purity alumina (95% and above) is used in refractory materials due to its high temperature underground and durability.

Applications in Medical and Aerospace

Medical Devices

High purity aluminum oxide is used in medical devices for its biocompatibility, strength, and resistance to chemical substance reactions.

Aerospace Components

The aerospace manufacture utilizes high purity alumina for its lightweight, strength, and resistance to extreme environmental conditions.

Choosing the rectify Purity Level

Factors to Consider

When selecting aluminum oxide purity, consider the specific requirements of your application, including temperature resistance, mechanical strength, and chemical stability.

Cost vs. Performance

Higher purity aluminum oxide typically comes at a higher cost. Weighing the benefits of increased performance against the undefined is essential in qualification an informed decision.

Future Trends

Advances in atomic number 13 Oxide Purification

Ongoing research and technological advancements are leading to more efficient methods of purifying atomic number 13 oxide, potentially reducing undefined and expanding its applications.

Emerging Applications

As sinlessness levels increase, fres applications for aluminum oxide carry on to emerge, peculiarly in high-tech and environmentally demanding fields.

Conclusion

Understanding the differences ‘tween aluminium oxide purity levels is crucial for selecting the right material for your needs. to each one grade offers unique properties and is suited to specific applications. By carefully considering the purity level, you can ensure optimal public presentation and cost-effectiveness for your project.

FAQs

1. What is aluminum oxide used for?

Aluminum oxide is used in a widely range of applications, including electronics, medical devices, aerospace components, industrial coatings, and as a catalyst in chemical substance reactions.

2. How is the purity of aluminum oxide measured?

The purity of atomic number 13 oxide is measured by the part of aluminum oxide content relative to impurities. Higher pureness grades have fewer impurities and high performance.

3. Why is high purity aluminum oxide more expensive?

High purity aluminum oxide is more expensive due to the complex and costly purification processes required to remove impurities and achieve the craved level of purity.

4. put up aluminum oxide whiteness affect production lifespan?

Yes, higher purity aluminum oxide generally offers better durability and resistance to wear and tear, which can extend the life of products made from it.

5. What industries benefit most from senior high purity atomic number 13 oxide?

Industries much as electronics, aerospace, medical, and high-tech manufacturing benefit the most from high sinlessness aluminum oxide due to its victor physical and chemical properties.