Factors Influencing Thermogravimetric Analysis Results

Thermogravimetric analysis (TGA) is a crucial thermal analysis technique used to assess the mass and temperature relationship of materials, providing insights into their thermal stability and composition. The accuracy of TGA is affected by various factors, including instrument conditions, experimental parameters, and sample properties.

1. Instrumental Influence

- Buoyancy Effects: As the sample heats, air buoyancy decreases, impacting weight readings. Additionally, convection currents can create a false sense of weightlessness.

- Volatilization: Gases escaping from the sample may condense elsewhere, leading to inaccurate weight loss measurements. Ensuring proper gas flow can mitigate this.

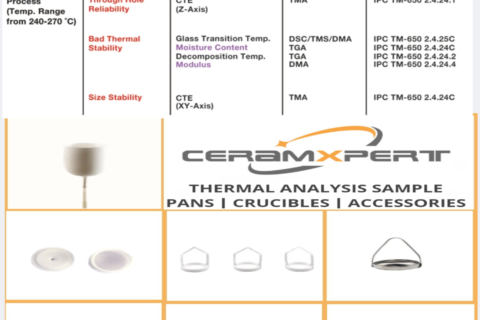

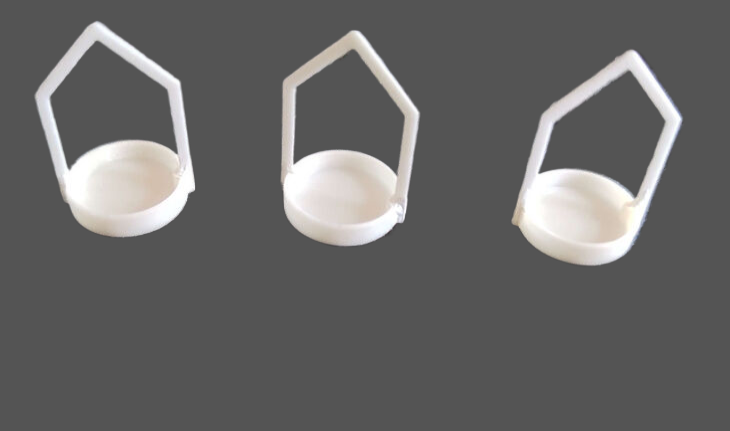

- Crucible Material: The crucible must be inert and non-reactive to prevent interference with the sample.

2. Operating Conditions

- Heating Rate: A faster heating rate can lead to temperature lags, affecting decomposition temperatures. Optimal rates vary between materials; polymers typically require 5-10°C/min, while metals may use 10-20°C/min.

- Sample Properties: Larger sample sizes and particle sizes can prolong the time to reach decomposition, while smaller particles enhance reaction rates.

- Atmospheric Conditions: The surrounding atmosphere affects TG curves. Consistent flow rates and gas purity are crucial for reliable results.

When purchasing laboratory instruments and consumables, prioritize quality and precision over price. Key considerations include clear experimental needs, reputable manufacturers, cost comparisons, and effective inventory management. Ensuring the validity of your experiments starts with the right materials.

At Ceramxpert, we understand the importance of high-quality thermal analysis solutions. Let’s explore how we can enhance your research!