Introduction to Thermal Analysis Equipment and Consumables: A Key to Material Performance, Quality Control, and Innovatio

Thermal analysis equipment and consumables are essential tools used across various industries, including materials science, pharmaceuticals, chemicals, food, and electronics. The primary focus of thermal analysis is on material property testing, quality control, and research and development. The selection of equipment and consumables should be based on the specific needs of the industry, testing objectives, temperature range, and precision requirements.

📌 Overview of Major Applications in Key Industries

Thermal analysis instruments (such as DSC, TGA, and synchronous thermal analyzers) and associated consumables (such as thermocouples and sample crucibles) measure the physical and chemical properties of materials under temperature changes. This supports material research, quality monitoring, and process optimization. Below are some of the typical industries and their applications:

🧩 Industry Applications and Needs

IndustryTypical Applications, Core Equipment/ConsumablesPurposeMaterials Science

Polymer glass transition, oxidation induction period; metal material thermal stability DSC, TGA, High-temperature molds, Nickel/Platinum cruciblesEvaluate high-temperature resistance, aging behavior, optimize formulations and processes

Pharmaceuticals & Biotech

Drug purity testing, protein denaturation temperature analysis, excipient compatibility DSC, TGA, and Aluminum cruciblesEnsure drug stability, effectiveness, and proper storage conditions

Chemicals & Petrochemicals

Catalyst activity evaluation, polymer degradation analysis, oil thermal stability testingSTA, High-temperature zirconia oxygen analyzersOptimize reaction processes, assess product lifespan, ensure production safety

Food & Agriculture

Starch gelatinization, oil oxidation stability analysis, food additive thermal behavior DSC, TGA, Control food processing quality, extend shelf life, optimize storage conditions

Research & Academia

New material synthesis mechanisms, nanomaterial thermal property analysis, phase change material characterization, Laser thermal conductivity tester, support basic research and technological breakthroughs, publish academic findings

Electronics & Semiconductors

Chip heat dissipation material testing, PCB thermal distribution analysis, electronic packaging material coefficient of thermal expansion, Thermal camera, enhance electronic device reliability, prevent overheating failure

✅ Driving Factors and Trends

- Technological Innovation Demand: As fields like new energy and biomedicine raise material performance standards, thermal analysis equipment is evolving toward higher precision (such as nanometer-scale resolution) and intelligence (AI data processing).

- Stricter Quality Control: Regulatory tightening (e.g., GMP for pharmaceuticals, environmental material standards) means companies must use thermal analysis to ensure product compliance.

- Expanding Industry Segmentation: The scope of thermal analysis is extending beyond traditional chemicals and materials into consumer electronics (e.g., 5G device heat dissipation) and green energy (e.g., battery thermal stability), broadening the application scenarios.

📌 Core Applications and Key Scenarios in Thermal Analysis

Thermal analysis technology measures the physical and chemical properties of materials (such as mass, heat, and size) under temperature variation, supporting R&D and quality control across industries. Here are key applications and the technologies used:

IndustryKey ApplicationCore TechnologyTesting TargetPlastics/Rubber

Oxidation induction period (assessing aging resistance), Glass transition temperature (Tg) measurement, TGAAntioxidant effects, product service life

Pharmaceuticals/Biotech

Drug purity analysis, curing degree testing (e.g., thermosetting resins), DSC, STADrug stability, production process optimization

Food

Starch gelatinization, oil oxidation stability testing, DSC processing suitability, and shelf-life assessment

Materials Science

Coefficient of thermal expansion (ceramics/metals), phase transition temperature (polymers), TMA, High-temperature resistance, structural stability

Electronics/Semiconductors

PCB heat dissipation performance, chip packaging material thermal stability, TGAE quipment reliability, prevention of overheating failure

Note: The technologies mentioned in the table are based on popular thermal analysis methods such as Differential Scanning Calorimetry (DSC), Thermogravimetric Analysis (TGA), and Thermomechanical Analysis (TMA), which together cover over 80% of industrial testing needs.

🧩 Thermal Analysis Equipment Selection Guide

🔍 Select Equipment Based on Testing Needs

Testing ObjectiveRecommended Equipment Models/BrandsApplicable Scenarios, Change (e.g., melting point)

Differential Scanning Calorimeter (DSC)Mettler Toledo DSC 3+Plastics, pharmaceuticals, purity analysis

Mass Change (e.g., weight loss)

Thermogravimetric Analyzer (TGA)Mettler Toledo TGA 2Polyolefin pipe carbon black content testing

Dimensional Change (thermal expansion)

Thermomechanical Analyzer (TMA)Mettler Toledo TMA/SDTA2+Ceramic, metal material coefficient of thermal expansion

Multi-parameter Synchronous Analysis

Synchronous Thermal Analyzer (STA)Netzsch STA 449 F5Material thermal decomposition kinetics

✅ Key Selection Criteria

- Temperature Range:

- Automation Needs:

- Precision Requirements:

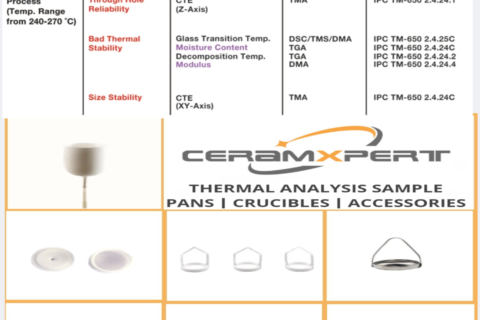

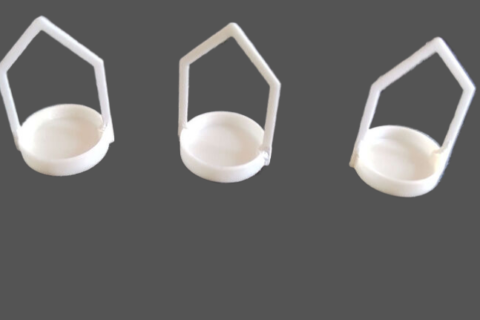

✅ Consumables Selection Guide

- Crucible Materials:

- Sensors:

✅ Popular Brands and Models

BrandPopular ModelsFeaturesMettler Toledo

DSC 3+, TGA 2High precision, highly automated, strong stability

Shimadzu

DSC-60A, TGA-50H, Suitable for the food and pharmaceutical industries, easy to operate

NETZSCH

STA 449 F3, DSC 204. Suitable for high-temperature material research, supports inert gas protection

TA Instruments

DSC Q20, TGA Q500Supports high-pressure DSC testing, suitable for polymer and composite material research

At CeramXpert, we specialize in providing high-quality, cost-effective thermal analysis consumables and solutions tailored to meet the diverse needs of industries worldwide. Let us help you optimize your material analysis and ensure accurate results every time.