Give us a call

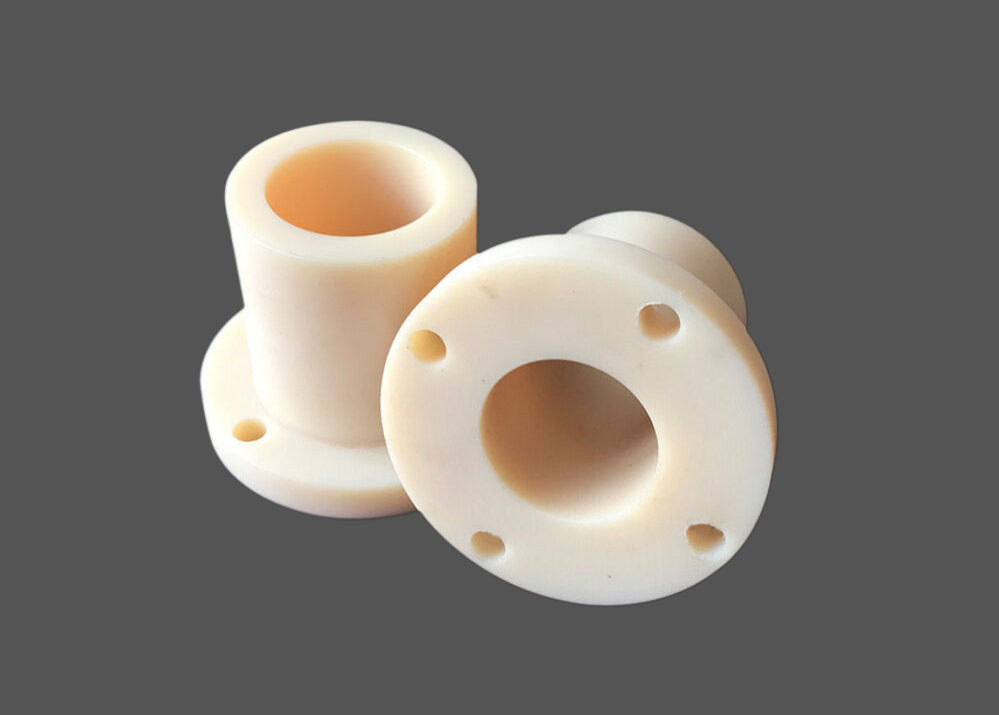

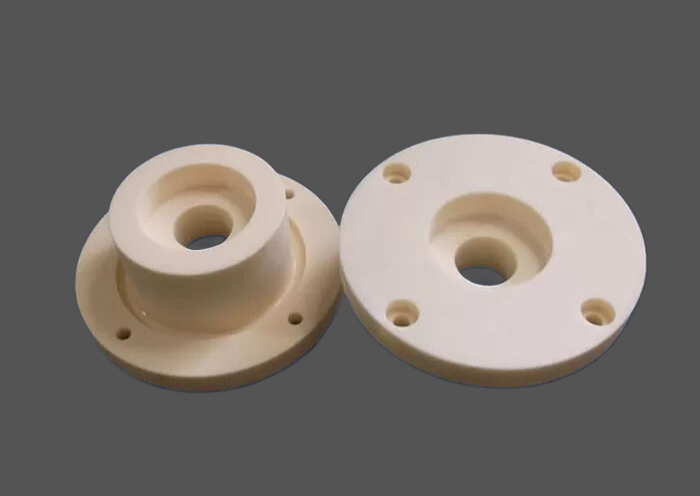

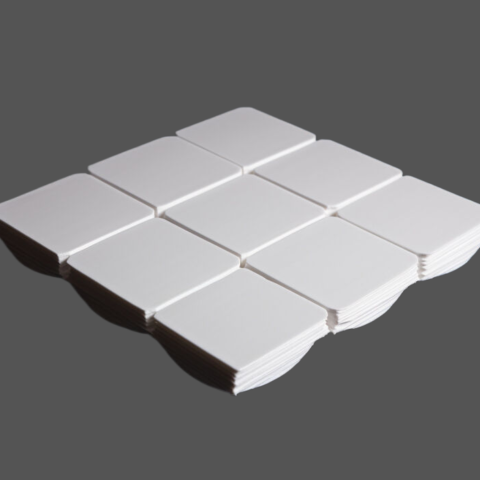

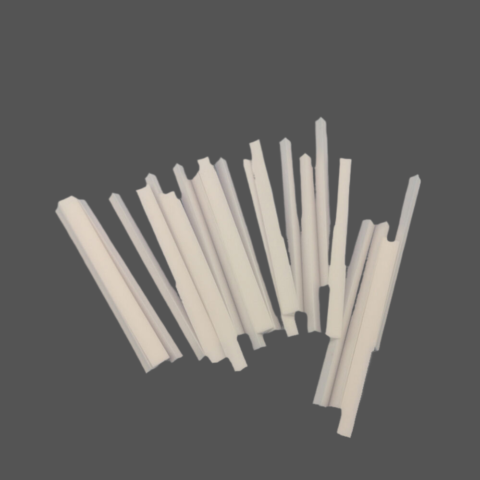

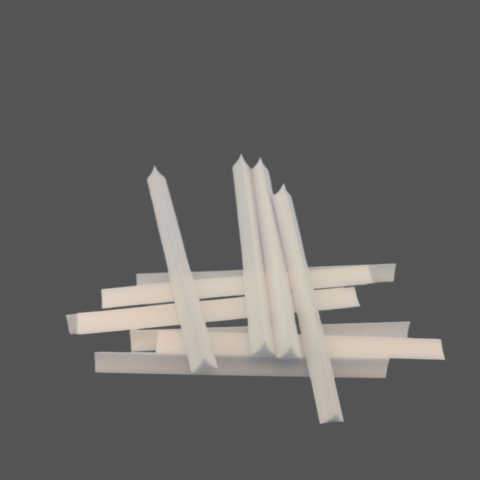

High-Quality Alumina Ceramic Flange for Precision Machining

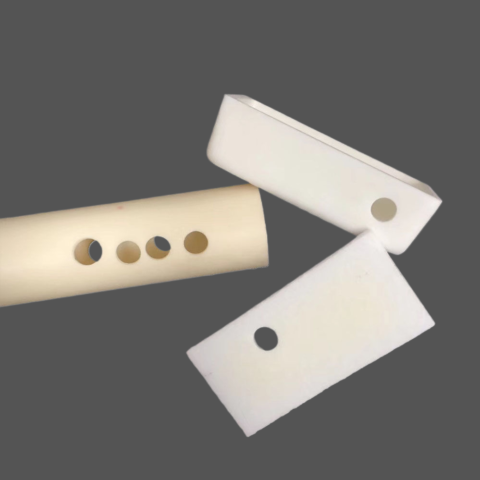

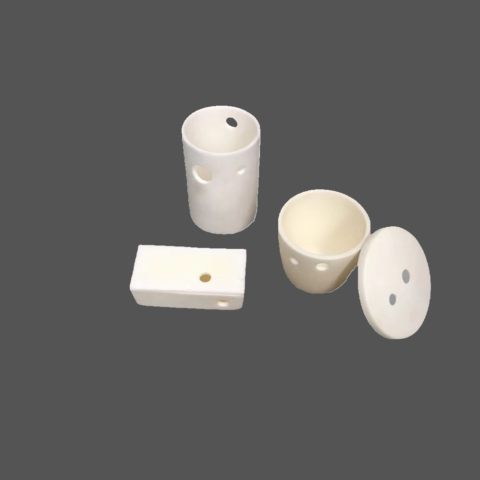

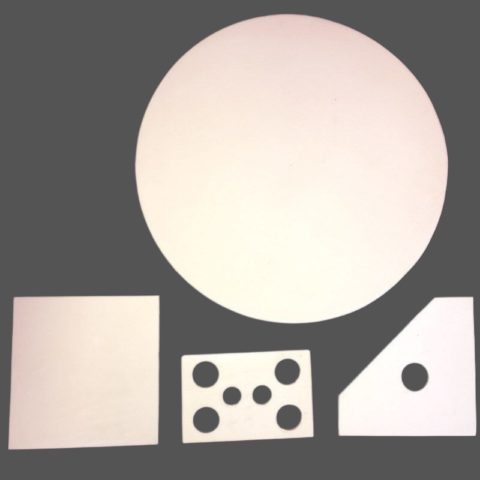

Alumina Ceramic Flange For Precision Machining Alumina ceramic flange is a lightweight, durable and strong flange that can withstand extremum temperatures and pressures without debasing or corroding.Available in various sizes and shapes.

Our High-Quality Alumina Ceramic Flange for Precision Machining is designed to meet the demands of precision engineering applications. Crafted from premium-grade alumina ceramic, this flange offers exceptional dimensional accuracy, surface finish, and thermal stability. Ideal for use in high-precision machining setups, vacuum systems, and semiconductor manufacturing, our ceramic flange ensures reliable performance and seamless integration. Upgrade to our high-quality alumina ceramic flange for enhanced precision and durability in your specific machining applications.

| SKU# | Material | Color | Purity | Maximum temperature |

| CX-AL-56001 | Alumina Ceramic | White | 99% | 1600 °C |

Notes for use:

Proper Alignment: Ensure precise alignment of the ceramic flange with other components or equipment to maintain dimensional accuracy and prevent misalignment during machining operations. Use precision mounting techniques and alignment tools to achieve optimal alignment for the desired machining results.

Surface Protection: Take precautions to protect the ceramic flange’s surface from scratches, abrasion, or contamination during handling and machining processes. Use soft, non-abrasive materials and avoid contact with abrasive particles or tools that could damage the ceramic surface and compromise its integrity.

Temperature Management: Monitor temperature fluctuations in the machining environment to prevent thermal stress or cracking of the ceramic flange. Maintain stable temperature conditions within the recommended limits to ensure optimal performance and longevity of the flange during precision machining operations.

Reviews

There are no reviews yet.