Give us a call

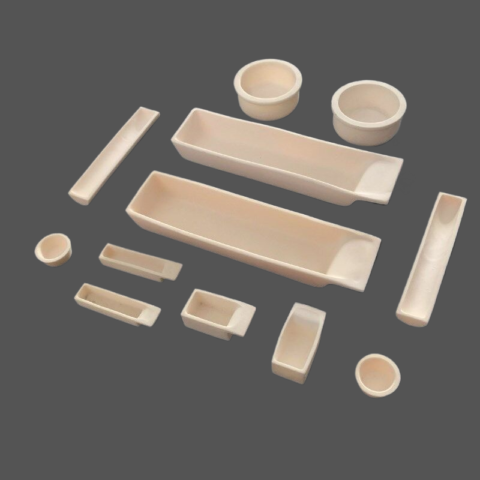

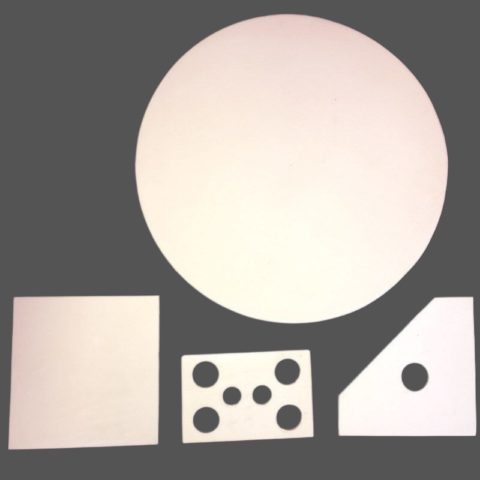

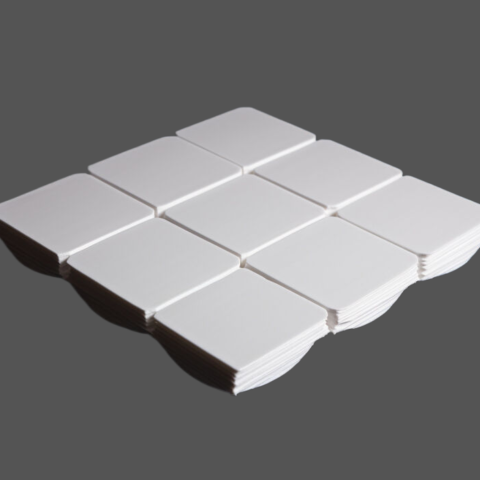

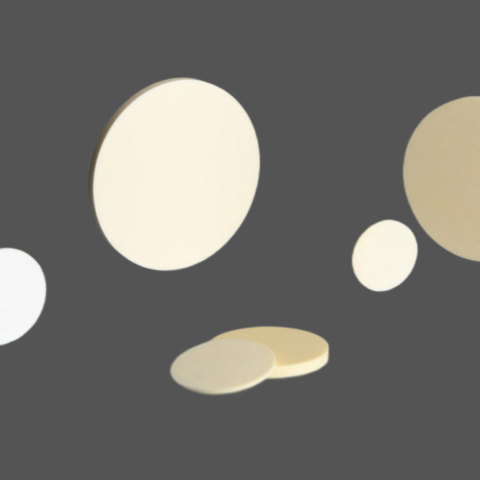

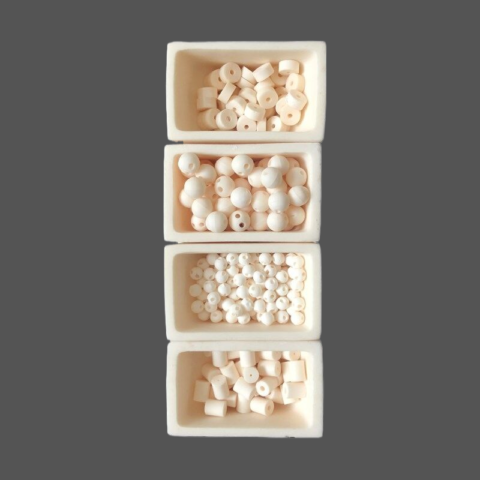

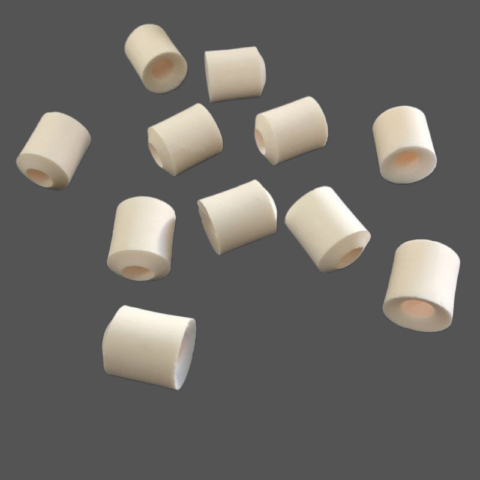

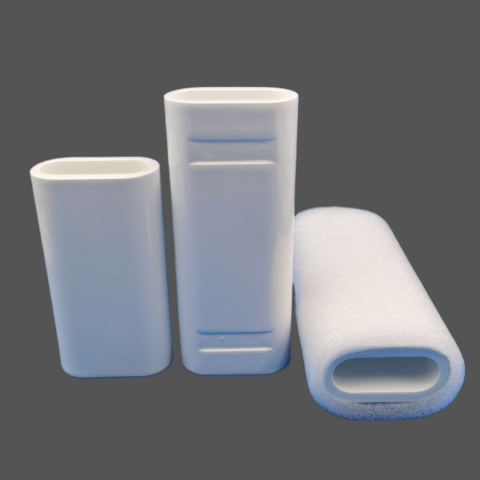

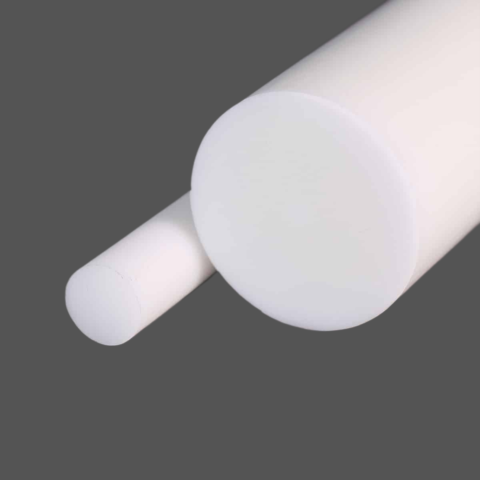

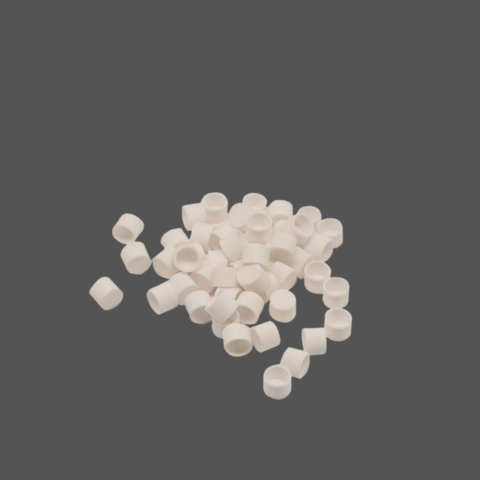

Top-Selling High-Quality Alumina Ceramic Parts

Alumina parts, known for their strength and durability, are utilized in electronics, aerospace, and automotive industries due to their resistance to high temperatures and corrosion. They offer exceptional electrical insulation and low thermal conductivity, making them ideal for diverse applications where reliability and performance are paramount.

Alumina components are crafted from alumina, a robust ceramic material highly resistant to both high temperatures and corrosion. These components find application across diverse industries, including electronics, aerospace, and automotive sectors.

Renowned for their exceptional strength and durability, alumina parts excel in enduring extreme conditions while maintaining structural integrity, thus suiting applications demanding reliability and performance. Commonly employed in manufacturing insulators, cutting tools, heating elements, and wear-resistant components, alumina parts deliver consistent performance.

A primary advantage of alumina parts lies in their outstanding electrical insulation properties, characterized by high dielectric strength. This makes them ideal for electrical and electronic applications, effectively withstanding high voltage without electrical leakage, thereby ensuring system safety and efficiency.

| SKU# | Material | Color | Purity | Maximum temperature |

| CX-AL-43001 | Alumina Ceramic | White | 99% | 1600 °C |

Notes for use:

Proper Handling and Installation: Handle alumina parts with care to prevent damage or breakage. During installation, ensure proper alignment and secure fitting to maintain their integrity and performance.

Compatibility Consideration: When using alumina parts in specific applications, consider factors such as chemical compatibility, temperature requirements, and mechanical stress to ensure optimal performance and longevity.

Reviews

There are no reviews yet.