Unlocking the Full Potential of Epoxy Resin with DSC, DMA, and TG-GC/MS 🔬

Epoxy resin curing is traditionally analyzed through thermochemical and thermorheological methods, with key indicators like glass transition temperature (Tg) driving performance in mechanical strength, friction, and permeability. Differential Scanning Calorimetry (DSC) and Dynamic Mechanical Analysis (DMA) are commonly used to study curing kinetics and rheological changes. While DSC monitors the degree of cure, DMA excels at detecting subtle changes in modulus and Tg, making it ideal for epoxy resin research.

But there’s more to epoxy resins than meets the eye! Despite similar curing conditions, differences in performance can still arise. Thermal Gravimetric Analysis (TGA) paired with Gas Chromatography/Mass Spectrometry (TG-GC/MS) reveals how volatile compounds within cured epoxy resins can affect long-term performance. Even when curing appears complete, residual volatile compounds can volatilize during use, leading to unexpected failures in electronic components.

Key Findings:

- DSC & DMA show similar curing trends in most samples, but TGA and TG-GC/MS expose hidden factors.

- Some materials show a 30% failure rate despite similar curing characteristics, suggesting volatile compounds are at play.

- Comprehensive thermal analysis is key to understanding the full behavior of epoxy resins beyond simple chemorheological tests.

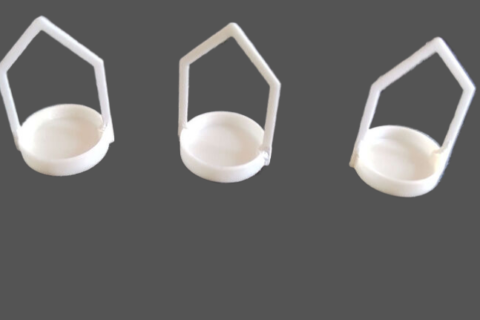

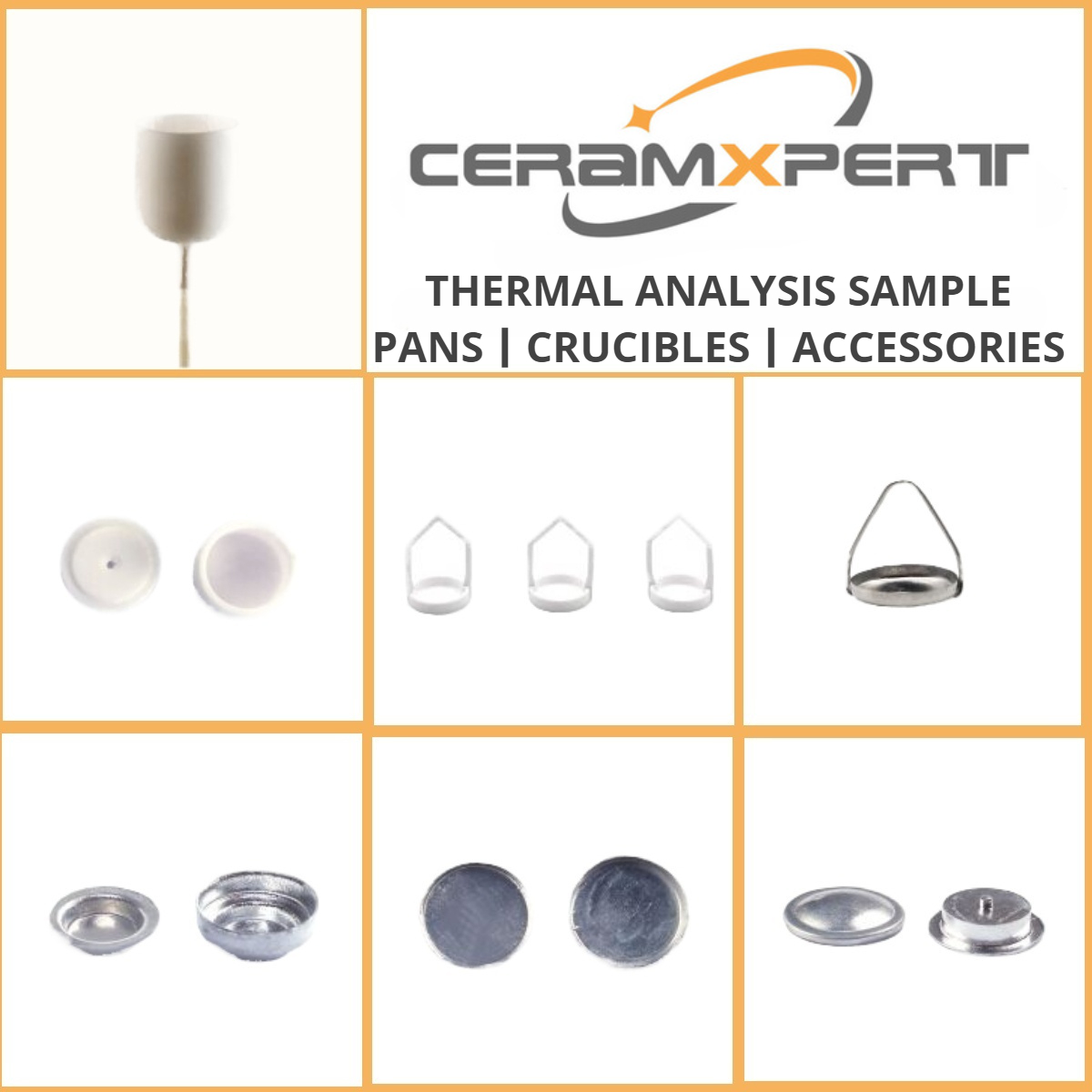

At CeramXpert, we specialize in providing high-quality, cost-effective consumables for advanced material analysis, including DSC, DMA, and TGA equipment. Let’s connect and explore how our products can enhance your epoxy resin research!

#EpoxyResin #MaterialScience #ThermalAnalysis #DSC #DMA #TGGCMS #EpoxyCuring #AdvancedMaterials #Thermogravimetry #ThermalCharacterization #CeramXpert #InnovationInMaterials #ElectronicsAssembly #ResearchAndDevelopment