Why Choosing the Right Crucible is Crucial in Thermal Analysis

Why Choosing the Right Crucible is Crucial in Thermal Analysis

Thermal analysis is a powerful technique used to characterize materials by observing their physical and chemical changes in response to temperature changes. However, the success of these experiments relies not only on the precision of the furnace or the heating rate but also on the choice of crucible material. In particular, paying attention to the crucible’s material can significantly impact the accuracy of your results and the longevity of your equipment.

Understanding Furnace Setup and the Impact on Crucible Selection

One of the most common setups in thermal analysis involves using a furnace with a tube that heats from the bottom. This design, while simple, introduces a challenge: uneven heating. As the furnace heats only from the bottom, the side walls of the furnace remain cool, causing a temperature gradient within the system. This can lead to significant stress on the crucible, particularly when exposed to rapid temperature changes.

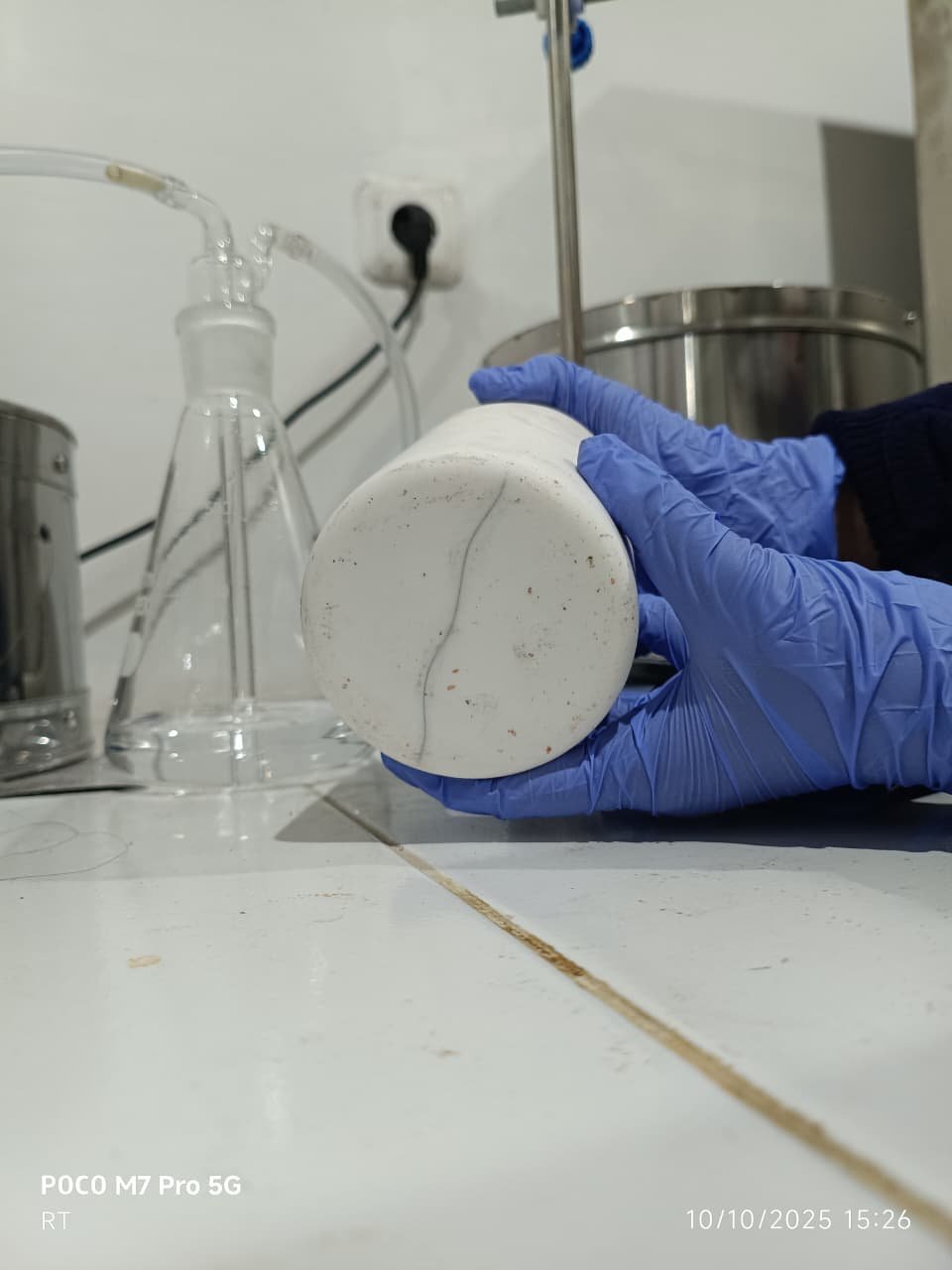

In such cases, using an alumina crucible, a material commonly chosen for its high thermal resistance and chemical stability, can help manage the stress. However, even the best materials can succumb to the pressures of uneven heating. Cracking is a common issue, especially when the heating rate exceeds safe limits, which is why temperature control is critical.

Why Cracking Happens and How to Prevent It

When conducting thermal analysis experiments, especially at high temperatures, cracking of the crucible is often a sign of uneven heating. The bottom of the crucible heats up rapidly, while the sides cool, creating thermal stress. As the material inside the crucible expands and contracts at different rates, the crucible may crack, compromising the integrity of the experiment.

To prevent this, it is essential to ensure that the furnace design promotes uniform heating. A sealed muffle furnace or a tube furnace is preferred, as these systems provide more even heating. Additionally, controlling the heating rate to around 5˚C per minute can help mitigate thermal shock and reduce the risk of cracking.

Why Alumina Crucibles and Alternatives Like Zirconia Are Key

Alumina crucibles are widely used due to their excellent high-temperature resistance and minimal reactivity with most sample materials. However, in some cases, even alumina may not withstand the extreme conditions created by uneven heating.

For those conducting experiments at higher temperatures or with more aggressive materials, switching to a zirconia crucible can be beneficial. Zirconia offers even better resistance to high temperatures and thermal shock, though it comes at a higher cost. Despite the expense, its durability can be worth the investment for high-precision experiments where crucible integrity is essential.

Conclusion

The choice of crucible is a fundamental aspect of any thermal analysis experiment. While alumina crucibles are a reliable choice, understanding the limitations of your furnace setup and using a more robust material, such as zirconia, may be necessary for long-term success. By paying careful attention to the furnace’s heating design and controlling the heating rate, you can significantly reduce the risk of crucible failure and ensure more accurate and reliable experimental outcomes.

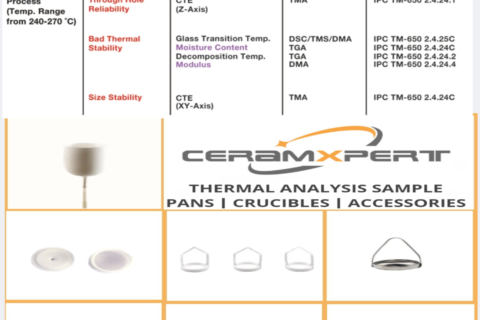

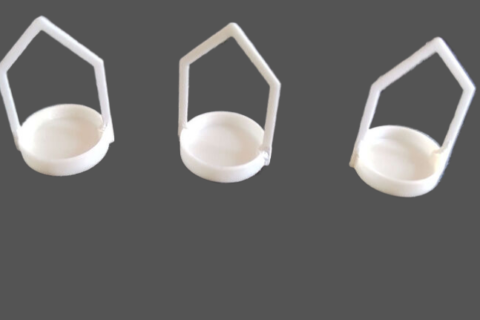

At CeramXpert, we specialize in providing high-quality, cost-effective crucibles and consumables that are designed to withstand even the most demanding thermal analysis conditions. For more information on our products or to discuss your specific requirements, feel free to reach out to us.