Give us a call

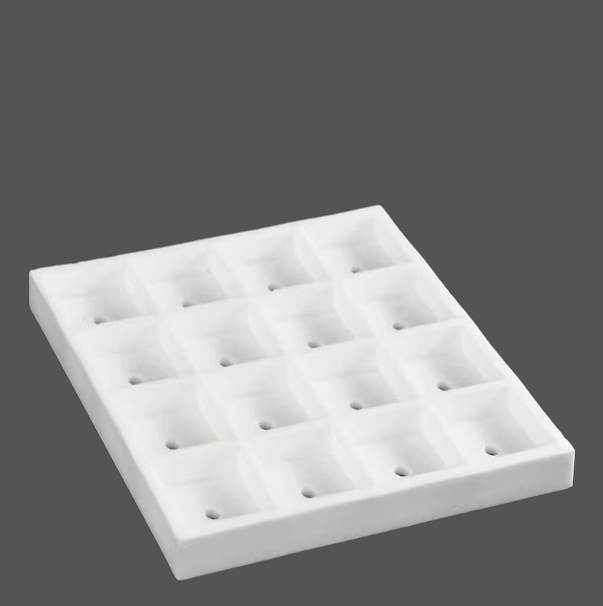

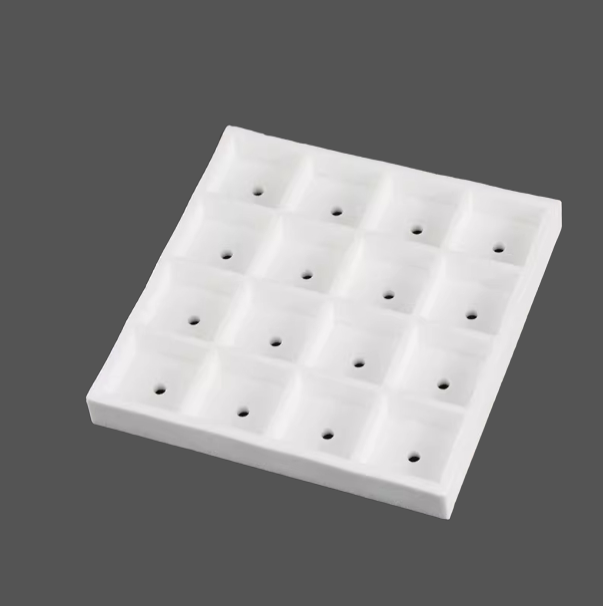

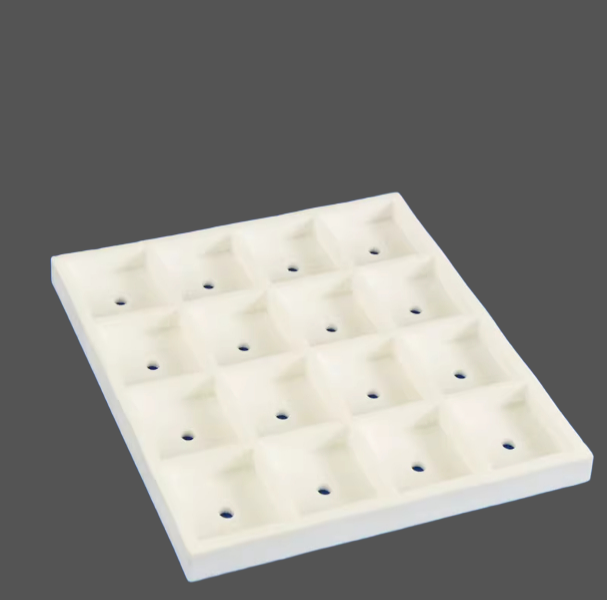

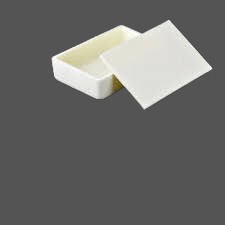

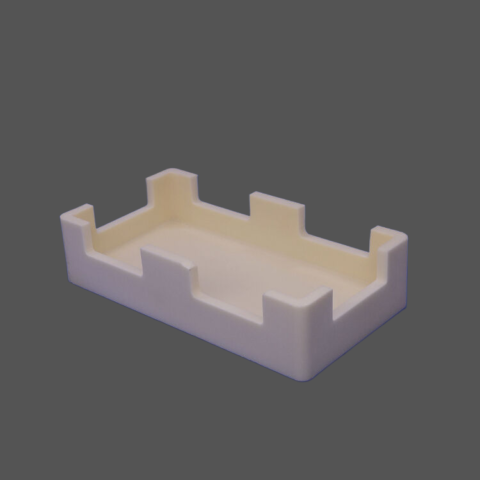

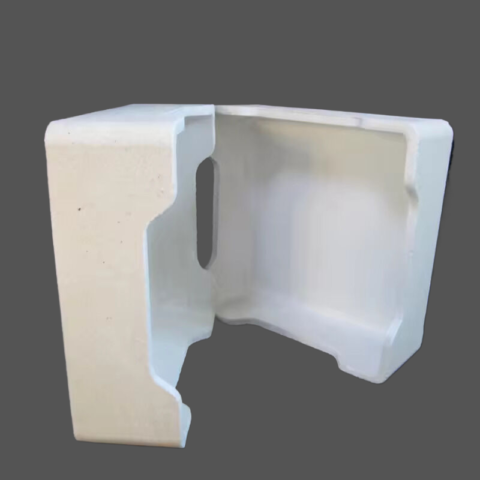

16-compartment perforated alumina crucible for Tube Furnace

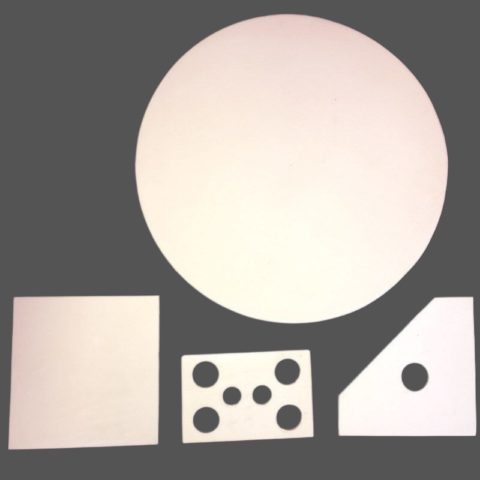

This 16-compartment perforated alumina crucible is engineered for precise and efficient sample separation in high-temperature applications. Manufactured from high-purity alumina (Al₂O₃ > 99%) using a slip-casting process, it offers high density, excellent thermal stability, and smooth, uniform surfaces inside and out.

Designed for continuous operation up to 1600°C, it provides excellent resistance to corrosion, wear, and thermal shock, making it ideal for analytical and industrial use.

This 16-compartment perforated alumina crucible is engineered for precise and efficient sample separation in high-temperature applications. Manufactured from high-purity alumina (Al₂O₃ > 99%) using a slip-casting process, it offers high density, excellent thermal stability, and smooth, uniform surfaces inside and out.

Designed for continuous operation up to 1600°C, it provides excellent resistance to corrosion, wear, and thermal shock, making it ideal for analytical and industrial use.

Package: 1 piece per pack

| SKU# | Material | Color | Purity | Maximum temperature |

| CX-AL-71001 | Alumina Ceramic | White | 99% | 1600 °C |

Specifications

-

Product Name: Alumina Square Crucible

-

Material: 99% Alumina (Al₂O₃)

-

Outer Dimensions (L × W × H): 93 × 93 × 11 mm

-

Wall Thickness: 3 mm

-

Square Cell Size: 20 × 20 mm

-

Manufacturing Process: Slip Casting / Press Casting

-

Firing Temperature: 1800°C

-

Operating Temperature: 1600°C

Applications

Suitable for laboratory and industrial analyses involving metal and non-metal samples, melting experiments, and thermal processing. Commonly used in tube furnaces for analytical research and material testing.

Usage Precautions for 99% Alumina Crucibles

-

Pre-drying: Before first use, place the crucible in an oven at approximately 105°C for 2 hours to remove any absorbed moisture.

-

Avoid Direct Flame: Do not heat directly with gasoline, acetylene, or alcohol torches to prevent cracking from uneven heating.

-

Maintain Distance from Heating Elements: Keep at least 2 cm between the crucible and heating elements (e.g., carbon tubes, SiC rods, or heating wires).

-

Control Heating/Cooling Rate:

-

Below 1200°C: ≤ 5°C per minute

-

Above 1200°C: ≤ 4°C per minute

-

Use controlled power cooling; avoid shutting off power suddenly at high temperatures to prevent thermal shock.

-

-

For Large Crucibles: Avoid direct contact with the furnace floor. Use high-temperature-resistant supports (e.g., corundum plates) to elevate the crucible, promote air convection, and extend service life.

Reviews

There are no reviews yet.