Give us a call

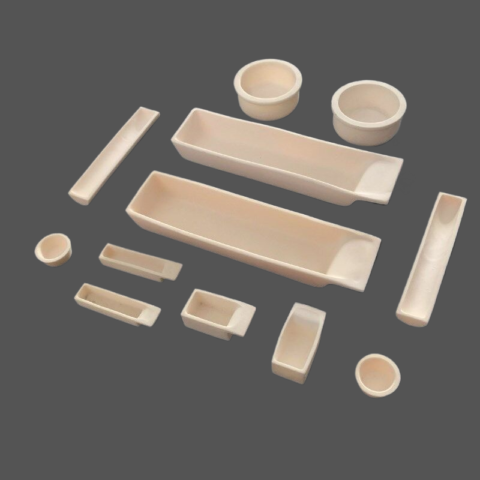

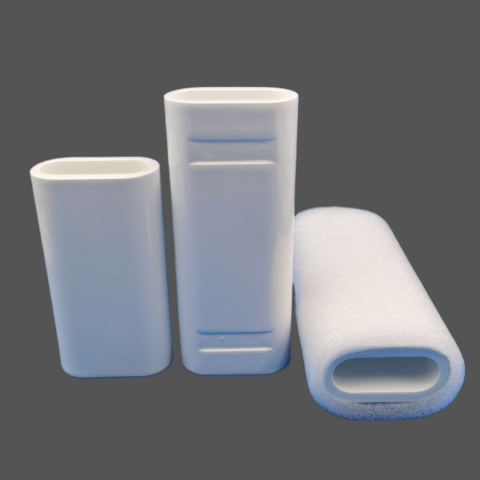

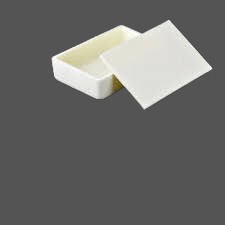

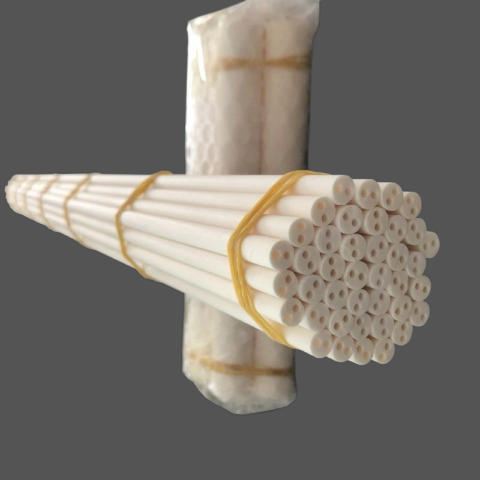

99 Alumina Cylindrical Crucibles with Threaded Lid | Airtight | Customizable

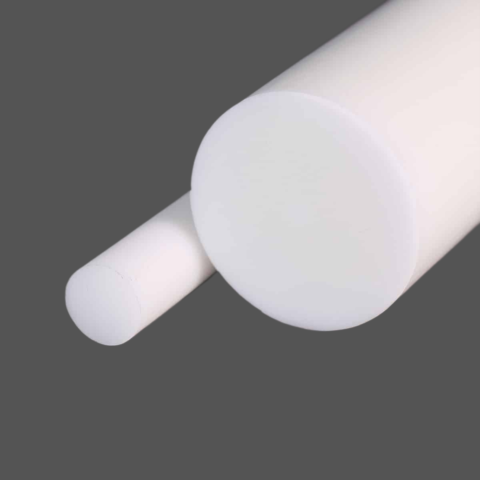

These 99 Alumina Cylindrical Crucibles with Threaded Lid are made from high-purity Al₂O₃ (>99%) using a precision slip-casting process, ensuring high density and smooth, uniform surfaces inside and out. The threaded design provides an airtight seal, minimizing contamination and preventing sample loss during high-temperature experiments.

Designed for continuous use up to 1600°C, these crucibles are ideal for controlled laboratory reactions, heat treatment, and research applications requiring high purity and thermal stability.

These 99 Alumina Cylindrical Crucibles with Threaded Lid are made from high-purity Al₂O₃ (>99%) using a precision slip-casting process, ensuring high density and smooth, uniform surfaces inside and out. The threaded design provides an airtight seal, minimizing contamination and preventing sample loss during high-temperature experiments.

Designed for continuous use up to 1600°C, these crucibles are ideal for controlled laboratory reactions, heat treatment, and research applications requiring high purity and thermal stability.

| SKU# | Material | Color | Purity | Maximum temperature |

| CX-AL-83001 | Alumina Ceramic | White | 99% | 1600 °C |

Available Sizes (Diameter × Height):

14 × 25 mm

25 × 30 mm

36 × 39 mm

63.5 × 60 mm

71.2 × 157.6 mm

Usage Instructions:

-

Heat and cool gradually with the furnace.

-

Avoid rapid temperature changes or direct flame contact.

-

Not recommended for metal smelting applications.

Precautions for Using 99% Alumina Crucibles

-

Pre-drying: Before first use, heat at approximately 105°C for 120 minutes to remove moisture.

-

Avoid direct flame: Do not use gasoline, acetylene, or alcohol torches to prevent cracking from uneven heating.

-

Maintain clearance: Keep at least 2 cm between the crucible and heating elements (e.g., carbon tubes, silicon carbide rods, heating wires).

-

Control heating/cooling rate:

-

Below 1200°C: ≤5°C per minute

-

Above 1200°C: ≤4°C per minute

-

Use controlled power cooling to avoid thermal shock.

-

-

Support positioning: For large crucibles, avoid direct contact with the furnace floor. Use corundum or other heat-resistant plates to elevate the crucible, enhance airflow, and extend service life.

Reviews

There are no reviews yet.