Give us a call

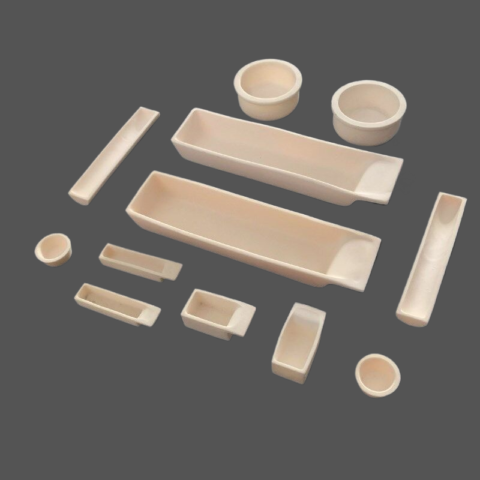

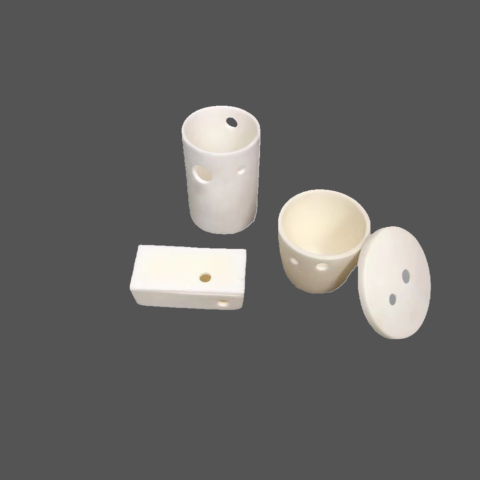

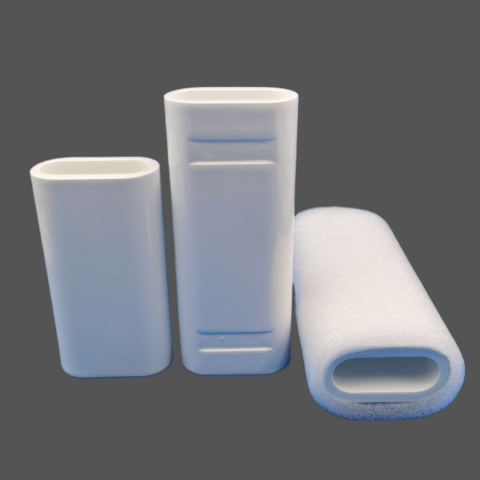

99% Alumina Corundum Funnel High-Temperature Resistant

This Alumina Corundum Funnel is made from high-purity Al₂O₃ (>99%) using a slip-casting process, ensuring high density, smooth interior and exterior surfaces, and excellent thermal stability. Designed for long-term use at temperatures up to 1600°C, it is ideal for laboratory and industrial high-temperature applications.

This Alumina Corundum Funnel is made from high-purity Al₂O₃ (>99%) using a slip-casting process, ensuring high density, smooth interior and exterior surfaces, and excellent thermal stability. Designed for long-term use at temperatures up to 1600°C, it is ideal for laboratory and industrial high-temperature applications.

Package: 1 piece per pack

| SKU# | Material | Color | Purity | Maximum temperature |

| CX-AL-79001 | Alumina Ceramic | White | 99% | 1600 °C |

Applications

-

High-temperature material handling and powder transfer

-

Suitable for metals, ceramics, and other high-temperature materials

-

Used in laboratory, industrial, and thermal processing applications

Usage Precautions for 99% Alumina Funnels

-

Pre-drying: Before first use, place the funnel in an oven at approximately 105°C for 2 hours to remove moisture.

-

Avoid Direct Flame: Do not heat directly with gasoline, acetylene, or alcohol torches to prevent cracking due to uneven heating.

-

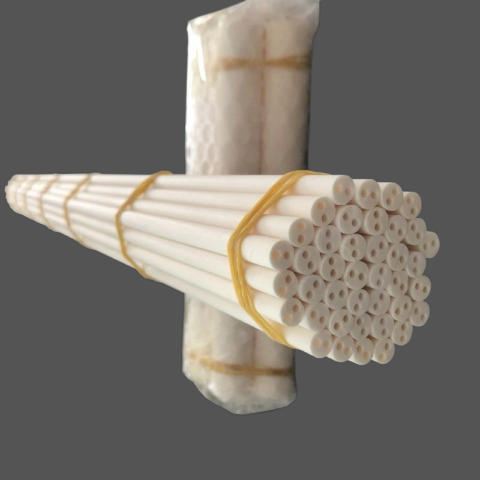

Maintain Distance from Heating Elements: Keep at least 2 cm between the funnel and heating elements (e.g., carbon tubes, SiC rods, heating wires).

-

Controlled Heating/Cooling:

-

Below 1200°C: ≤ 5°C per minute

-

Above 1200°C: ≤ 4°C per minute

-

Use controlled power cooling; avoid sudden shutdown at high temperatures to prevent thermal shock.

-

-

For Large Funnels or Crucibles: Avoid direct contact with the furnace floor. Use high-temperature-resistant supports (e.g., corundum plates) to improve airflow and extend lifespan.

Reviews

There are no reviews yet.